Stephen’s note: New Year’s resolutions aren’t my favorite, but I made one anyway last year: Don’t watch the news.

I’m proud to say I kept it. The news is a never-ending feed of the worst things happening on a given day. That’s part of the reason why I co-founded The Rational Optimist Society. We help our members understand, appreciate, and take advantage of the innovations revolutionizing our world for the better, so they can confidently flourish.

And today, I’m sharing a recent edition of our Rational Optimist Diary on nanotech and nuclear fusion. An incredibly bright future is now unfolding.

(By the way, if you’d like to join us in The Rational Optimist Society, this week is your last chance to become a founding member. Go here.)

***

Imagine deploying microscopic submarines into your bloodstream. Their mission: identify and destroy early stage cancer cells before they can gain a foothold in your body.

That’s nanotechnology—which refers to manufacturing at a nanometer scale. A nanometer is 1/100,000th the width of a human hair.

But nanotech doesn’t just mean “very, very small.” Nanotech is a way of building things by assembling individual atoms, one by one. Atoms are the smallest building blocks in the universe. With atomic-level engineering, we can create new materials and structures that are otherwise impossible.

Like what? The book Nanosystems says a motor as small as a grain of sand could theoretically be powerful enough to propel a car. Or a desktop-sized nano factory that could instantly create anything—from food to furniture—by assembling it atom by atom. The Star Trek replicator brought to life!

Full-blown nanotech is still a distant dream. But we know it works because it's already running inside of us.

Every living cell in your body is a nano-factory. A single cell has more working parts than a Boeing 747 airplane. These microscopic machines build everything from brain tissue to bone with atomic precision.

We're just now learning to program these natural machines through technologies like CRISPR. Scientists are getting better and better at “deleting” cancer-causing genes, eradicating rare diseases, and controlling mosquito-borne plagues.

Nanotech could one day create real-life superheroes. I’m serious. Nanomachines could let you stay underwater for half an hour with no scuba tank by helping your red blood cells carry more oxygen. Atomic-scale engineering could enhance your vision, letting you see in the dark.

|

But if you really want to see our nanotech future, look in your phone. Inside that slim rectangle is a computer chip with billions of electronic switches called transistors. They were manufactured with the closest thing to atomic-scale nanotech we have today.

The chip in the latest iPhone is smaller than your thumbnail. Yet it has 19 billion transistors spaced just five nanometers apart.

Every year, chipmakers manufacture more of these atomic-scale switches than all the grains of wheat and rice grown on Earth combined.

Almost all the tech progress in our lifetime has come from chipmakers figuring out how to cram more transistors onto microchips. The NASA supercomputer that guided Neil Armstrong to the moon had 2,000 transistors. Your iPhone has nearly 10 million times more computing power.

SpaceX uses the power of modern chips to catch rockets. It was not even remotely possible to do this 20 years ago. The computing power required to analyze wind speeds, rocket trajectory, and dozens of other variables in real time did not yet exist.

Inside the cleanest rooms on Earth sit the most expensive machines ever built. They manipulate matter at scales smaller than a virus and operate at temperatures hotter than the sun.

Taiwan Semiconductor (TSMC) has made the chips inside every iPhone since 2014. According to WIRED Magazine: “Every six months, just one of TSMC’s 13 foundries… carves and etches a quintillion transistors for Apple.”

TSMC also produces Nvidia’s chips, the latest of which has 80 billion transistors packed onto a single piece of silicon. Imagine writing thousands of perfectly formed letters on a grain of rice with a pencil. Impossible! Not for TSMC. Instead of rice, it prints billions of transistors onto silicon wafers.

My friend who’s worked in TSMC’s football field-sized factories in Taiwan says they’re the most incredible buildings he’s ever seen.

Workers pass through security tighter than most airports. They suit up in special white "bunny suits" that cover every inch of skin. Then they walk through air-shower chambers that blast filtered air to remove any particles like dust.

The air inside TSMC's manufacturing floor is 100,000 times cleaner than a hospital operating room. The water used in the chipmaking process is around 10 million times purer than tap water. It’s too pure to drink, as it would leach minerals from your body.

Each chip goes through over 1,000 steps and takes about three months to finish. They're handled almost entirely by ceiling-mounted monorail robots because humans would contaminate the process. It’s no wonder TSMC’s newest fabrication facilities, or “fabs,” cost $20 billion apiece.

If Walmart closed tomorrow, you could shop at Costco. If Bank of America went bust, you could wire your money to Wells Fargo.

But if you’re Apple and you want a cutting-edge chip for the next iPhone, there’s only one company you can call: TSMC. And TSMC can only create these chips using one company's machines: ASML.

Advanced Semiconductor Materials Lithography (ASML) created a machine so complex, no other company on Earth can replicate it. It’s Extreme Ultraviolet (EUV) tool is the key to making the latest, greatest, fastest chips.

Each EUV machine is as heavy as a jumbo jet, packed with 100,000 precision parts and 2 kilometers of cables, all working in perfect harmony. It “prints” transistors into wafers measuring only five nanometers wide. Three million transistors could fit inside the period at the end of this sentence.

The system of mirrors inside this machine are so perfectly smooth that if you scaled one up to the size of California, it wouldn't have a bump higher than a millimeter.

Moving just one EUV tool requires a logistics operation worthy of a military campaign: 40 shipping containers, three cargo planes, and a fleet of 20 trucks. Price tag: $300 million.

Without ASML, there would be no iPhone. No Nvidia. No ChatGPT.

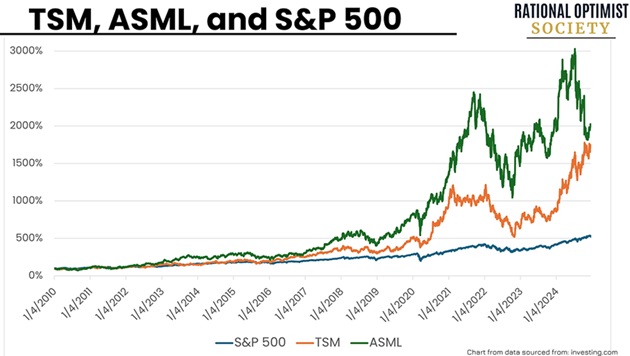

TSMC and ASML are the most advanced manufacturing companies in the world, by far. Technological supremacy is great for business. TSMC and ASML’s stocks are both up more than 15-fold since 2010.

Every major tech breakthrough of our time rides on the back of semiconductors. AI took off when chips finally became powerful enough to mimic human brains. Solar power gets cheaper every year because solar cells are essentially simple semiconductors, made using similar processes as chips.

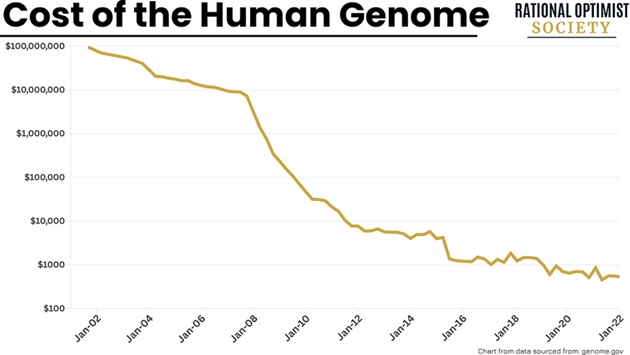

Not long ago, reading a person's complete genetic code cost $95 million. Today, thanks to tiny chips that can scan DNA like a superfast barcode reader, we can do it for less than $500—and in a few hours. That’s a 200,000-fold improvement

If you want to predict the future, pay attention to technologies riding the chip wave. Energy is the bedrock of innovation, but chips are the building blocks of technological revolutions.

The chip industry already produces more objects yearly than all other factories in human history combined. And we're just getting started.

A breakthrough in nuclear fusion

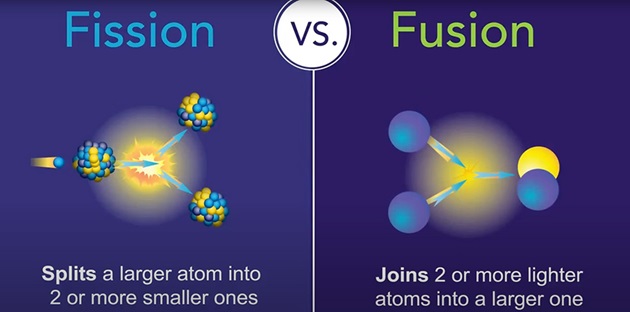

Deep in the sun’s core, billions of atoms smash together each second, releasing the heat that warms our planet. This process is called nuclear fusion. For 70 years, scientists have tried—and failed—to recreate it.

Now, a New Zealand startup has made a breakthrough in our quest to create a star on Earth.

Today’s nuclear plants run on fission, which splits atoms apart. Nuclear fusion works in reverse. It squeezes atoms together.

Source: Teledyne Imaging

When atoms “fuse” together, they unleash mind-boggling amounts of energy. Just 1 gram, the size of a bread crumb, could power your home for over 50 years.

But getting atoms to fuse is the hardest engineering challenge we’ve ever attempted. Atoms naturally repel each other. To overcome this, you must heat a puff of gas to over 180 million degrees Fahrenheit. That's about six times hotter than the sun’s core.

Then you must turn this superheated gas into "plasma," which is so hot it instantly vaporizes anything it touches. And you must maintain these extreme conditions long enough to capture energy and turn it into electricity.

For decades, only governments were in the fusion business. Now a wave of innovators are joining the race. New Zealand-based OpenStar recently created and contained a plasma cloud at around 540,000 degrees Fahrenheit in its first experimental reactor.

OpenStar turned the traditional fusion reactor design on its head. Instead of surrounding the plasma with magnets, it put the magnets inside the plasma itself. This allowed it to contain the plasma inside a vacuum chamber for 20 seconds. And it achieved this in under two years and for less than $10 million!

Helion Energy, backed by OpenAI CEO Sam Altman, is taking a different approach. It’s building what amounts to a plasma cannon. They fire two rings of plasma at each other at over a million miles per hour. When these rings collide, they create fusion and generate electricity directly. Helion has raised $500 million and promised to power Microsoft's data centers by 2028.

In Massachusetts, Commonwealth Fusion Systems is building SPARC. It’s a $1.2 billion reactor that uses powerful magnets to create an invisible bottle, keeping plasma floating in space like a miniature star.

SPARC has 18 super magnets, each powerful enough to lift an aircraft carrier. Each magnet weighs 30 tons and contains 200 miles of special tape, carefully wound for over 120 hours into dense coils. Here’s what it looks like.

Source: The New York Times

Fusion is a problem worth solving. Success would give us limitless clean, safe energy. Fusion reactors run on deuterium, found in ordinary seawater. Unlike traditional nuclear power, there's no risk of meltdowns.

At the recent Roots of Progress conference in Berkeley, I asked several energy experts what they thought of fusion. Verdict: Even if the tech works, it’s decades away from powering our homes. The extreme temperatures needed make fusion fundamentally more expensive than other energy sources.

But progress is accelerating. The next few years will tell us whether fusion can become the biggest energy breakthrough since we captured fire.

Stephen McBride

Chief Analyst, RiskHedge

PS: If you liked this, consider signing up for The Rational Optimist Society here. We publish a new Diary every Sunday. We also have a podcast, and we publish monthly “Deep Dives” on big important tech trends like 3D printing, fracking, nuclear energy, brain chips, and more.

After this week, the opportunity to become a founding member ends.